As the world grapples with climate change, energy security, and sustainability challenges, the quest for innovative solutions to our growing energy demands has become more pressing than ever. One of the most promising avenues for a cleaner, greener future lies in the realm of renewable energy, where harnessing the power of nature can provide a reliable and sustainable alternative to fossil fuels. Among the various technologies vying for attention, Mechanical Heat Recovery (MHR) stands out as a game-changer, capable of unlocking vast amounts of wasted energy from industrial processes and converting it into usable heat and power.

Understanding Renewable Energy Sources

As the world shifts towards a more sustainable future, renewable energy sources have become an increasingly vital component of our global energy landscape. Renewable energy, generated from natural resources that can be replenished over time, offers a cleaner, more sustainable alternative to traditional fossil fuels. Among the most promising renewable energy sources are solar, wind, hydropower, geothermal, and biomass. Each of these sources has its unique advantages and limitations.

Still, they all share a common goal: to reduce our reliance on finite fossil fuels and mitigate the devastating impact of climate change. By harnessing the power of these renewable energy sources, we can create a more sustainable, environmentally friendly energy system that benefits our planet, economy, and communities. In this guide, we’ll delve into mechanical heat-recovery technology, an innovative approach revolutionising how we think about renewable energy.

Benefits of Mechanical Heat Recovery System

Mechanical heat-recovery systems offer many benefits, making them an attractive solution for industries and businesses looking to reduce their environmental footprint and energy costs. One of the most significant advantages of these systems is their ability to reduce energy consumption, significantly leading to substantial cost savings.

By harnessing waste heat and converting it into usable energy, businesses can decrease their reliance on traditional fossil fuels and lower their energy bills. Mechanical heat-recovery systems can also help reduce greenhouse gas emissions, making them an important tool in the fight against climate change.

Furthermore, these systems can also increase the overall efficiency of industrial processes, leading to improved productivity and competitiveness. Another key benefit is the extended equipment lifespan, as the system reduces the machinery load and wear and tear. Implementing a mechanical heat recovery system can transform a business’s bottom line while contributing to a more sustainable future.

How MHR Works: The Science behind the Technology

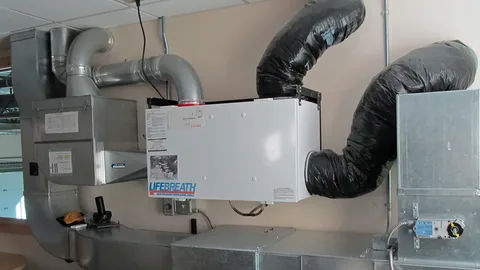

At the heart of Mechanical Heat-Recovery (MHR) technology lies a sophisticated process that harnesses the power of waste heat to generate clean energy. The science behind MHR is rooted in the principles of thermodynamics, where heat energy is transferred from one medium to another. In an MHR system, a specialized heat exchanger captures waste heat from industrial processes, power generation, or vehicle exhausts.

This waste heat is then converted into a usable form of energy, such as electricity or thermal energy, through cleverly designed mechanisms. The process begins with the absorption of heat by a refrigerant, which is then pumped through a closed-loop system. As the refrigerant flows, it expands and contracts, driving a turbine or generator that produces electricity.

The cooled refrigerant then returns to the heat exchanger, where it can absorb more heat and repeat the cycle. This continuous process allows MHR systems to recover up to 90% of waste heat, making it a highly efficient and effective means of generating renewable energy. By tapping into this previously wasted resource, MHR technology has the potential to significantly reduce greenhouse gas emissions and our reliance on fossil fuels.

Applications of Mechanical Heat Recovery Unit

A mechanical heat-recovery unit finds diverse applications across industries and sectors, contributing significantly to energy efficiency and sustainability efforts.

Industrial Processes

A mechanical heat-recovery unit can capture waste heat from various processes such as drying, baking, or chemical reactions in manufacturing facilities. This recovered heat can then be utilized to preheat incoming air or water, reducing the energy required for heating and lowering operational costs.

Commercial Buildings

Mechanical heat-recovery units are crucial in commercial buildings’ HVAC systems. By recovering heat from exhaust air, these units can preheat fresh air entering the building, improving indoor air quality and reducing heating costs during colder months.

Residential Settings

In residential applications, a mechanical heat recovery unit, often integrated into ventilation systems, helps maintain comfortable indoor temperatures while minimizing energy consumption. These units enhance energy efficiency and indoor air quality by exchanging heat between outgoing and incoming air streams, making them popular in modern home construction and renovations.

Wastewater Treatment Plants

Mechanical heat-recovery units are utilized in wastewater treatment plants to recover heat from effluent streams. This recovered heat can be repurposed for various onsite processes such as sludge, anaerobic digestion, or space heating, reducing energy costs and environmental impact.

Data Centers

In data centres with high cooling loads, mechanical heat-recovery units can extract heat from server exhaust air and transfer it to other facility parts, such as office spaces or water heating systems.

Principles of Heat Recovery Technology

At the heart of mechanical heat-recovery technology lies a fundamental principle: harnessing waste heat and converting it into a usable form of energy. This innovative approach is based on the notion that heat, often discarded as a byproduct of industrial processes, can be recovered and reused to generate power, reduce energy consumption, and minimize environmental impact.

The technology exploits the thermal energy in waste heat streams, such as those generated by industrial processes, power plants, and even HVAC systems, to produce a valuable resource. By leveraging the principles of thermodynamics, heat recovery technology can efficiently capture and convert waste heat into electricity, steam, or hot water, providing a reliable and sustainable energy source. This process reduces the amount of energy wasted, decreases greenhouse gas emissions, and helps mitigate the strain on the global energy grid.

Types of Mechanical Ventilation Heat Recovery Systems

Mechanical ventilation heat-recovery systems encompass a range of technologies designed to improve indoor air quality and energy efficiency simultaneously. Here are some types of mechanical ventilation heat-recovery systems:

Cross-Flow Heat Exchangers

Cross-flow heat exchangers are a common choice within mechanical ventilation heat-recovery systems for mechanical ventilation heat-recovery systems. These systems allow two airstreams to pass perpendicular to each other, facilitating efficient heat transfer between the exhaust and incoming fresh air.

Counter-Flow Heat Exchangers

Another prevalent option among mechanical ventilation heat recovery systems is counter-flow heat exchangers. In these systems, the exhaust and fresh air streams flow in opposite directions, maximizing the thermal exchange efficiency as they pass through the heat exchanger.

Rotary Heat Exchangers

Rotary heat exchangers are dynamic components within mechanical ventilation heat-recovery systems. They consist of rotating wheels with heat-absorbing material, facilitating continuous heat transfer between the airstreams as the wheel spins.

Plate Heat Exchangers

Plate heat exchangers play a vital role in mechanical ventilation heat-recovery systems. These exchangers feature stacked metal plates with alternating fluid channels, enabling efficient heat exchange between the exhaust and incoming air streams.

Run-Around Coil Systems

Lastly, run-around coil systems are integral to mechanical ventilation heat-recovery systems. These systems utilize separate coils in the exhaust and supply air streams, connected by a circulating fluid loop, ensuring effective heat recovery while minimizing cross-contamination risks.

Overcoming Challenges and Implementing MHR in Your Business

As you embark on the journey to harness the power of mechanical heat-recovery (MHR) technology, you’ll undoubtedly encounter obstacles that may seem daunting. From navigating complex regulatory frameworks to addressing concerns about upfront costs, it’s essential to be prepared to overcome these hurdles.

One of the most significant challenges is the initial investment required to implement MHR systems, which can be a substantial barrier for many businesses. However, by conducting a thorough cost-benefit analysis, you can demonstrate the long-term savings and sustainability benefits that MHR technology can bring to your organization. Additionally, working with experienced professionals and industry experts can help you navigate the implementation process, ensuring a smooth transition to MHR.

By understanding the challenges and developing a strategic plan to address them, you can successfully integrate MHR technology into your business, reducing your environmental footprint and increasing your bottom line. With careful planning, collaboration, and a commitment to sustainability, you can unlock the full potential of mechanical heat-recovery and reap the rewards of a more efficient, eco-friendly operation.

The Power of Mechanical Ventilation and Heat Recovery

Mechanical ventilation & heat recovery systems are powerful tools for improving indoor air quality while reducing energy consumption. These systems extract stale air from enclosed spaces, such as buildings or homes, and replace it with fresh outdoor air. During this process, mechanical ventilation and heat recovery systems utilize heat exchangers to transfer heat from the outgoing air to the incoming air stream, thus preheating the fresh air before it enters the building.

This efficient heat exchange helps maintain comfortable indoor temperatures year-round while minimizing energy loss. By continuously circulating and filtering air, these systems also remove pollutants, allergens, and excess moisture, creating healthier and more comfortable indoor environments.

The power of mechanical ventilation & heat recovery lies in their ability to provide consistent air quality and thermal comfort, all while reducing reliance on traditional heating and cooling methods. As sustainability and energy efficiency become increasingly important considerations in building design and operation, these systems play a crucial role in achieving environmental goals without compromising comfort or health.

Conclusion

In conclusion, mechanical heat-recovery technology’s potential to revolutionize energy utilization cannot be overstated. Innovative engineering and strategic implementation offer a sustainable pathway towards reducing carbon emissions and mitigating climate change. By tapping into renewable energy sources and maximizing efficiency through heat recovery, industries and communities can significantly decrease their environmental footprint while cutting operational costs. As technology evolves and awareness grows, embracing these advancements will be crucial for a greener and more sustainable future.

FAQs

What is mechanical heat-recovery?

Mechanical heat-recovery involves capturing waste heat from various processes or systems and reusing it to preheat air or water. This technology reduces the energy needed for heating, enhancing efficiency and sustainability.

How does mechanical heat-recovery work?

Mechanical heat-recovery transfers heat from exhaust air or waste streams to incoming air or water using heat exchangers or recovery units. This preheated fluid is then used for heating, recovering energy that would otherwise be wasted.

What are the benefits of mechanical heat recovery?

Mechanical heat recovery reduces energy consumption, lowers utility bills, and decreases environmental impact. It improves energy efficiency, process performance, and financial savings, making it an attractive investment.

What types of applications benefit from mechanical heat-recovery?

It benefits various sectors, such as manufacturing, commercial buildings, wastewater treatment plants, and power generation facilities. However, applications producing high-temperature exhaust streams, such as industrial ovens and furnaces, benefit most.

Are there limitations to mechanical heat-recovery?

Yes, limitations include:

- Waste heat source temperature and volume.

- Availability of suitable heat sinks.

- Initial capital investment.

Efficiency may vary based on design, operation, and maintenance practices.

How can businesses implement mechanical heat-recovery systems?

Businesses start with energy audits to identify waste heat sources. They then collaborate with engineers to design customized solutions and ensure proper installation, commissioning, and maintenance for optimal performance.

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |