As the world grapples with the challenges of climate change and rising energy costs, businesses and individuals seek innovative solutions to minimize their environmental impact while keeping expenses in check. One often overlooked yet highly effective strategy is the implementation of air heat-recovery systems. By harnessing the waste heat generated by industrial processes, buildings, and other applications, air heat recovery technology offers a potent tool for reducing energy consumption, slashing carbon emissions, and boosting bottom lines.

Understanding Air Heat-Recovery Technology

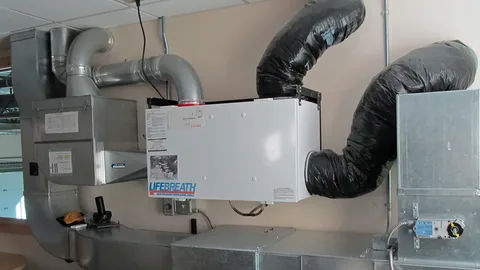

At its core, air heat-recovery technology is an innovative solution that harnesses the heat energy that would otherwise be wasted in industrial processes, commercial buildings, and residential spaces. This ingenious system works by capturing the heat energy from exhaust air streams, such as those from ventilation systems, data centres, and industrial processes, and transferring it to a fluid, which can then be used to provide heating or cooling.

By recovering and reusing this heat energy, businesses and individuals can significantly reduce their energy consumption, lower their carbon footprint, and reap substantial cost savings. With the ability to recover heat from various sources, air heat-recovery technology can transform how we think about energy efficiency and sustainability.

Harnessing Energy Efficiency through Fresh Air Heat Recovery Unit

Harnessing Energy Efficiency through Fresh Air Heat Recovery Unit

As the world grapples with the challenges of climate change, energy efficiency has become a critical component of sustainable development. One innovative solution that has gained significant traction in recent years is the air heat-recovery unit. This revolutionary technology harnesses the power of waste heat to reduce energy consumption and carbon emissions. By integrating a fresh air heat recovery unit into your building’s ventilation system, you can effectively recover the energy that would otherwise be lost through ventilation and reuse it to heat or cool your space.

This cutting-edge technology works by transferring the heat energy from the extracted air to the fresh air supply, minimizing the need for fossil fuels and reducing your carbon footprint. With the ability to recover up to 80% of the heat energy, air heat-recovery units offer a significant opportunity for buildings to reduce their energy consumption, lower operating costs, and contribute to a more sustainable future.

Benefits of Air Heat-Recovery – Energy Savings and Carbon Reduction

Imagine harnessing the power of wasted heat energy and transforming it into a valuable resource that saves you money and reduces your carbon footprint. This is precisely what air heat-recovery systems can achieve. By recovering and reutilizing the heat energy that would otherwise be lost to the atmosphere, these innovative systems can help you maximize your energy savings and minimize your environmental impact.

The benefits of air heat-recovery are multifaceted and far-reaching. For one, it can significantly reduce your energy bills by up to 30%, freeing up valuable resources for other areas of your business or home. Additionally, by decreasing the demand for traditional heating systems, air heat-recovery can also extend the lifespan of your equipment, reducing maintenance costs and downtime. However, the most compelling benefit of air heat-recovery is its potential to reduce greenhouse gas emissions and mitigate the devastating effects of climate change.

By leveraging this cutting-edge technology, you can make a meaningful contribution to a more sustainable future while enjoying the financial benefits of reduced energy consumption.

Applications of Heat Exchange Ventilation System

The heat-exchange ventilation system, also known as air heat-recovery, has many applications that can significantly benefit from its energy-efficient and environmentally friendly technology. In commercial settings, such as offices, hospitals, and shopping centers, heat exchange ventilation system can be integrated into the building’s ventilation system to recover heat energy from exhaust air and transfer it to fresh air, thereby reducing the load on heating and cooling systems.

In industrial settings, heat-exchange ventilation systems can be used to recover heat from industrial processes, such as manufacturing, and utilize it to heat or cool buildings, reducing energy consumption and costs. In residential settings, this system can provide a cost-effective and sustainable way to heat and cool homes, reducing the reliance on fossil fuels and minimizing carbon emissions.

Furthermore, heat-exchange ventilation systems can be applied in agricultural settings, such as greenhouses and livestock farms, to create a more sustainable and energy-efficient environment. These various applications can significantly reduce energy consumption, lower energy bills, and minimize their carbon footprint by harnessing the power of air heat-recovery.

Strategies for Reducing Carbon Footprint with Air Heat-Recovery

Reducing carbon footprint through air heat-recovery entails implementing strategies that optimize energy efficiency and minimize wastage. Here are some effective approaches:

Maximizing Heat Recovery Efficiency

Enhancing the efficiency of heat recovery systems is crucial. Employing high-quality heat exchangers and optimizing their design to maximize heat transfer between outgoing and incoming air streams ensures minimal energy loss and maximal heat recapture.

Integration with Renewable Energy Sources

Combining air heat-recovery systems with renewable energy sources such as solar or geothermal power amplifies sustainability efforts. Utilizing clean energy to power ventilation and heat recovery processes further reduces reliance on fossil fuels, slashing carbon emissions.

Comprehensive Building Envelope Optimization

Improving building insulation and sealing air leaks prevents heat loss, reducing the workload on heating systems. This, in turn, enhances the effectiveness of air heat-recovery by minimizing the temperature differential between incoming and outgoing air, lowering energy consumption and carbon emissions.

Demand-Controlled Ventilation

Implementing demand-controlled ventilation systems ensures that air heat-recovery operates only when necessary, aligning ventilation rates with actual occupancy and air quality requirements. By avoiding unnecessary operation, energy usage is optimized, leading to a reduced carbon footprint.

Regular Maintenance and Monitoring

Scheduled maintenance and continuous monitoring of air heat-recovery systems are essential. This ensures equipment operates at peak efficiency, minimizing energy waste and maximizing heat recovery potential. Additionally, identifying and addressing issues promptly prevents system degradation, prolonging its lifespan and sustainability impact.

Cost-Benefit Analysis of Residential Energy Recovery Ventilator

When implementing an air heat-recovery system in your residential space, the cost-benefit analysis is one of the most crucial considerations. While the initial investment in a residential energy recovery ventilator (ERV) may seem daunting, the long-term benefits far outweigh the costs. Not only can an ERV help reduce your energy consumption by up to 70%, but it can also lead to significant cost savings on your utility bills. In fact, according to the U.S. Department of Energy, a typical residential ERV system can pay for itself in just 5-7 years through energy savings alone.

Additionally, many governments and utility companies offer rebates and incentives for homeowners who invest in energy-efficient technologies like ERVs, further reducing the upfront cost. But the benefits continue beyond there. By reducing your energy consumption and carbon footprint, you’ll contribute to a more sustainable future for future generations. With the average ERV system lasting up to 20 years, the long-term benefits of this technology are undeniable.

Design Considerations for Optimal Heat Recovery Systems

When designing an optimal heat recovery system, several key considerations must be considered to maximize energy savings and minimize carbon footprint. One of the most critical factors is selecting the right heat exchanger technology, which can significantly impact the system’s efficiency and overall performance. The type of heat exchanger used will depend on the specific application, with options including plate heat exchangers, shell and tube heat exchangers, and rotary heat exchangers.

Additionally, the system’s piping design and layout must be carefully planned to minimize pressure drops and optimize fluid flow. Furthermore, integrating controls and sensors is crucial to ensure the system operates optimally, with real-time monitoring and adjustments to maintain peak efficiency. Consideration must be given to the system’s maintenance and upkeep, with easy access to components and regular cleaning schedules essential to prevent fouling and maintain optimal performance.

By carefully considering these design factors, businesses and organizations can unlock the full potential of air heat-recovery systems, achieving significant energy savings and reducing their environmental impact.

Residential Heat Recovery Ventilator – Health and Comfort Benefits

The residential heat recovery ventilator (HRV) is a game-changer for improving your home’s health and comfort. By constantly exchanging stale air for fresh air, an HRV system ensures that the air inside your home is clean, fresh, and free of pollutants. This is especially important for people who suffer from allergies or respiratory issues, as it helps to remove allergens and irritants from the air.

Moreover, an HRV system helps to regulate the humidity levels in your home, preventing the growth of mould and mildew, which can exacerbate health issues. The fresh air circulation provided by an HRV system can help to reduce fatigue, improve sleep quality, and boost overall energy levels. By removing stale air and introducing fresh air, an HRV system creates a more comfortable and healthy indoor environment, making it an essential component of a modern, eco-friendly home.

Conclusion

In conclusion, using air heat-recovery systems is a pivotal strategy in pursuing sustainable and energy-efficient building practices. By harnessing the latent energy within exhaust air, these systems significantly reduce operational costs and contribute to a substantial decrease in carbon emissions. Through meticulous design, implementation, and ongoing optimization, businesses and homeowners alike can realize tangible benefits in environmental stewardship and economic savings. As industries prioritize sustainability, air heat-recovery emerges as a cornerstone solution in the global effort to combat climate change and foster a greener future.

FAQs

How does air heat-recovery benefit the environment?

Air heat-recovery significantly reduces the demand for fossil fuels by utilizing waste heat that would otherwise be lost. Lowering energy consumption helps decrease greenhouse gas emissions and contributes to a smaller carbon footprint, thus promoting environmental sustainability.

What types of systems are used for air heat-recovery?

Several systems are employed for air heat-recovery, including heat exchangers, heat pumps, and ventilation systems with heat recovery units. These systems vary in complexity and efficiency, offering solutions tailored to different applications and budgets.

Can air heat recovery be applied in both residential and commercial settings?

Air heat recovery suits various environments, including homes, offices, schools, hospitals, and industrial facilities. Its versatility allows for customizable solutions to meet each setting’s specific ventilation and heating needs.

What are the economic benefits of implementing air heat-recovery?

Implementing air heat-recovery can save significant costs by reducing energy consumption and lowering heating bills. While initial investment costs may vary depending on the system’s complexity, the long-term financial benefits typically outweigh the upfront expenses.

Are there any maintenance requirements for air heat-recovery systems?

Like any mechanical system, air heat-recovery requires regular maintenance to ensure optimal performance and longevity. This may include cleaning filters, inspecting components for wear and tear, and scheduling professional servicing. Adhering to a maintenance schedule can maximize energy savings and prolong the system’s lifespan.

| Other Good Articles to Read |

| Blogs-Nation |

| Blogs-Peoples |

| Bryan Smith Blogs |

| intellect blogs |

| the fault in our blogs |

| blogs eu |

| oz forums |

| recruitment blogs |

| zet blogs |

| id blogs |

| Blog Studio legale |

| blogs map |

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |